Hypergolic propellants are used in rocket propulsion to power the rocket engine using spontaneous combustion. This project involved the development of a spray ignition setup for the combustion of hypergolic propellants. A theoretical injector system was designed and validated. Experiments were performed using High Speed Imaging to study impingement characteristics of a triplet injector. This work was conducted under the guidance of Prof. Arindrajit Chowdhury at the Internal Combustion Engines Laboratory, Department of Mechanical Engineering, Indian Institute of Technology Bombay.

Some results are listed below -

- A combustion chamber withstanding a pressure of 30 bar was modelled on SolidWorks and structural analysis was conducted on ANSYS.

- A theoretical injector system was modelled and validated.

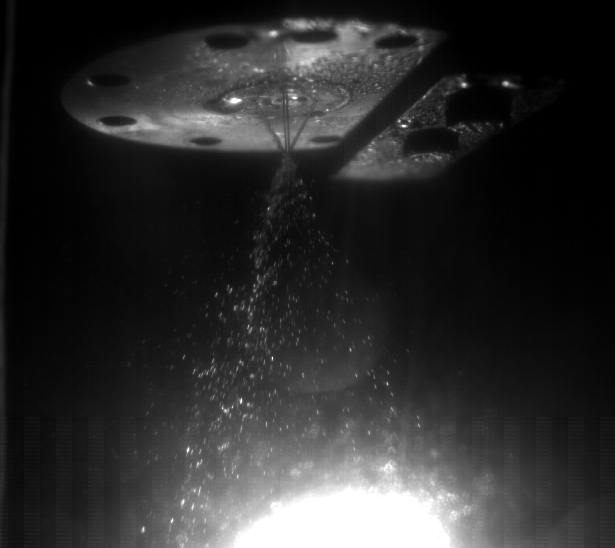

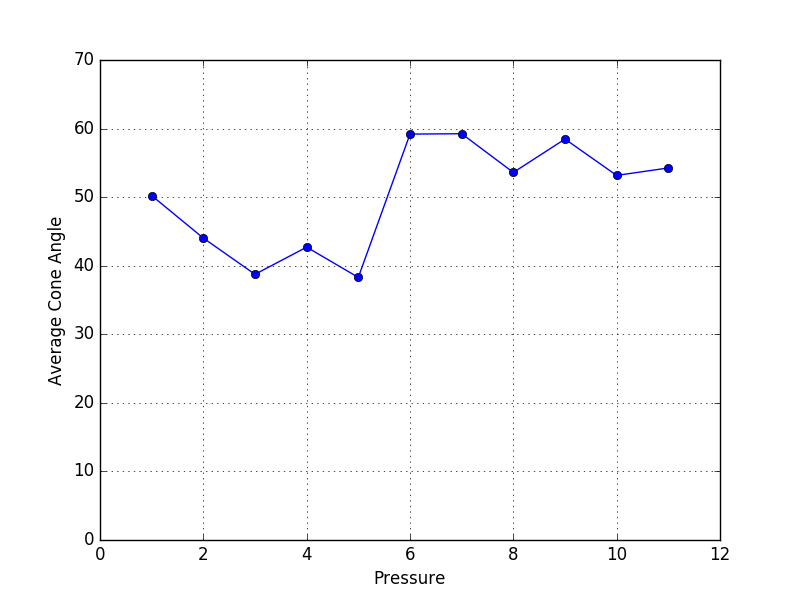

- Three types of propellants were tested experimentally with High Speed Imaging to study the impingement characteristics of the triplet injector.

Note: The propellants shown in the image are Water-Water for pressures 1, 6 and 10 bar from left to right.